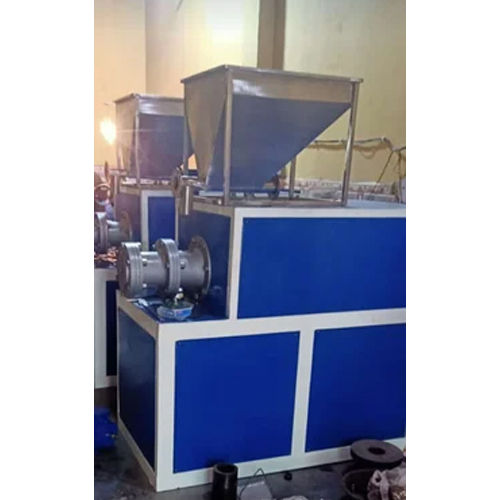

Automatic Rice Corn Puff Making Machine

1300000 INR/Piece

Product Details:

- Product Type Automatic Puffed Rice Making Machine

- General Use Rice Making Machine

- Material Stainless Steel

- Type Ball Gum Plant Snacks Extruder

- Computerized Yes

- Automatic Yes

- Control System PLC Control

- Click to View more

X

Automatic Rice Corn Puff Making Machine Price And Quantity

- 1300000 INR/Piece

- 1 Piece

Automatic Rice Corn Puff Making Machine Product Specifications

- ECO Friendly Low Noice

- Rice Making Machine

- PLC Control

- Yes

- Yes

- Automatic Puffed Rice Making Machine

- Ball Gum Plant Snacks Extruder

- Stainless Steel

- Yes

- Free Stand

Automatic Rice Corn Puff Making Machine Trade Information

- Cash in Advance (CID)

- 10 Piece Per Month

- 30 Days

- All India

Product Description

An automatic rice corn puff making machine is specialized equipment designed to produce rice and corn puffs which are popular snacks known for their light and crispy texture Here are the key components and features typically found in such a machine

Raw Material Handling The machine handles raw materials such as rice grits corn grits or a mixture of both which are the primary ingredients for making rice and corn puffs

Mixing and Conditioning Raw materials are mixed with water and possibly other ingredients like salt oil or flavorings to form a dough or batter This mixture is conditioned to achieve the right consistency and texture

Extrusion and Shaping The conditioned dough or batter is fed into an extruder equipped with specific dies for rice and corn puffs The extruder shapes the mixture into the desired puff shapes such as balls curls or rings

Cutting and Sizing The extruded puff shapes are cut to the desired length using cutting blades or rollers integrated into the machine This ensures uniformity in size and shape of the puffs

Drying and Puffing The cut puff shapes are then dried and puffed to achieve their characteristic light and crispy texture This process typically involves hot air drying or frying depending on the desired final product specifications

Frying or Baking After drying the puffs may undergo frying in hot oil or baking in an oven to further enhance their texture and flavor

Seasoning Once fried or baked the rice and corn puffs are seasoned with flavors such as cheese barbecue salt etc This can be done automatically through a seasoning drum or similar equipment

Cooling and Packaging After seasoning the puffs are cooled down to room temperature and then automatically packed into bags or containers The packaging process includes weighing sealing and labeling

Control Systems Modern automatic rice corn puff making machines are equipped with advanced control systems to monitor and regulate various parameters such as temperature speed and ingredient ratios This ensures consistent quality and efficiency in production

Cleaning and Maintenance These machines are designed for easy cleaning and maintenance often featuring stainless steel construction to meet hygiene standards and extend the machines lifespan

Capacity and Customization The machines come in various capacities ranging from smallscale production suitable for startups to largescale industrial units capable of producing significant quantities of rice and corn puffs per hour They can also be customized based on specific production requirements and regional preferences

In conclusion an automatic rice corn puff making machine automates and optimizes the entire production process of rice and corn puffs ensuring high efficiency consistent quality and hygiene standards in snack production

Enter Buying Requirement Details

Other Products in 'Puff Making Machine' category

|

A P ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS